HIPS (High Impact Polystyrene)-2938

HIPS is a modified form of polystyrene (PS), enhanced by adding rubber elastomers - typically polybutadiene - into the polystyrene matrix to improve its impact strength and toughness.

- HIPS (High Impact Polystyrene)

- Significantly enhanced impact strength; resistant to cracking and breaking.

- Excellent electrical insulation properties.

- Good dimensional stability.

Quantity

- Product Features

- Product Specifications

Product Features

- High Impact Strength:

The primary advantage of HIPS—resistant to cracking and breaking under stress.

- Excellent Electrical Insulation:

Suitable for electronic and electrical applications requiring safety and reliability.

- Dimensional Stability:

Maintains shape and precision over time, ideal for structural applications.

- Easy to Process:

Supports various manufacturing techniques such as injection molding, helping reduce production costs and complexity.

- Cost-Effective:

Relatively inexpensive, making it ideal for mass production.

- Good Surface Finish:

Easy to print, paint, or coat, enhancing the final product's appearance.

Product Specifications

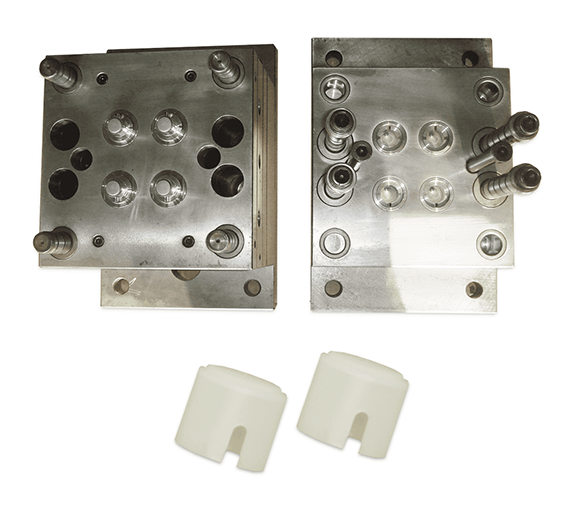

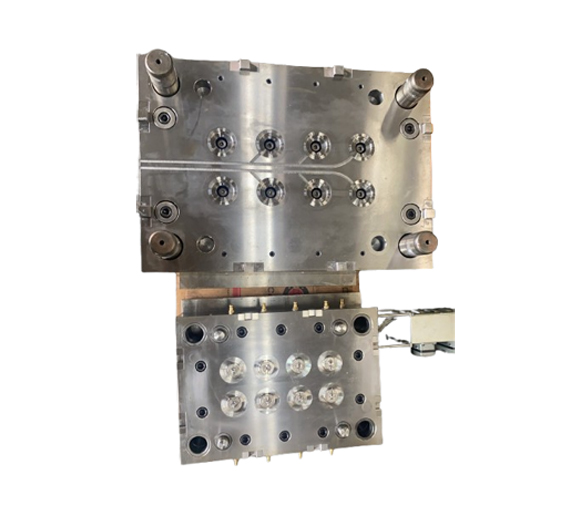

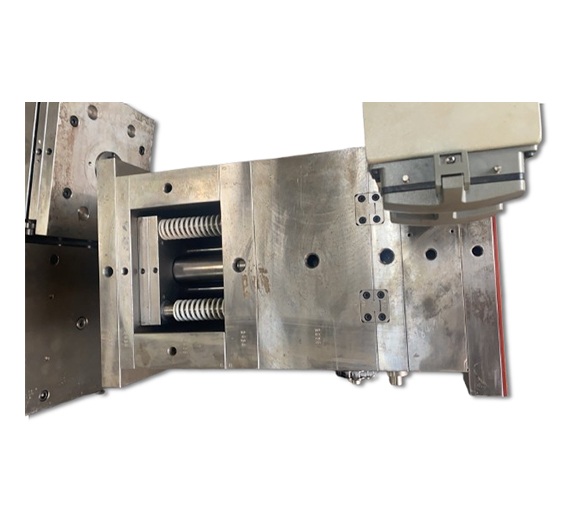

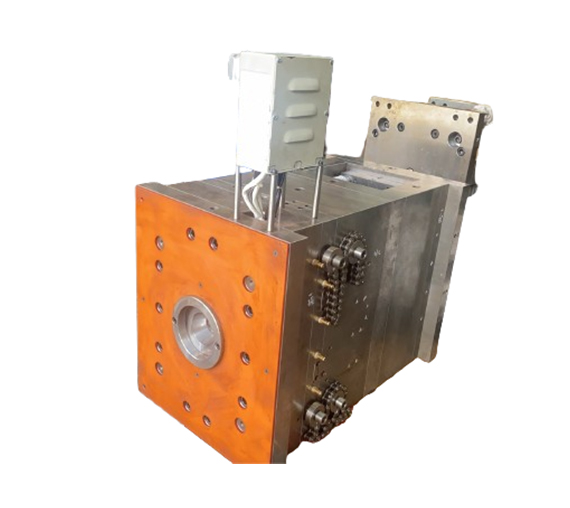

| Mechanical Part | 2938 |

|---|---|

| Material | Stainless Steel, Carbon Steel |

| Color | Nickel White |

| Mold Base Supplier | De Wei |

| Mold Base Material | S50C |

| Core Material | STAVAX420 |

| Cavity Number | 8 |

| Gating System | Hot Runner |

| Gate Location | (Not provided) |

| Mold Life | 300,000 shots |

| Design Software | UG, CAD |

| Mold Flow Analysis Software | Moldex 3D |

| Molding Material | HIPS |

| Mold Size | Length:500 Width:350 High: 716 mm |

| OEM and ODM | Acceptable |

| Packaging | Wooden case packaging or according to your requirements |

Previous product

Previous product