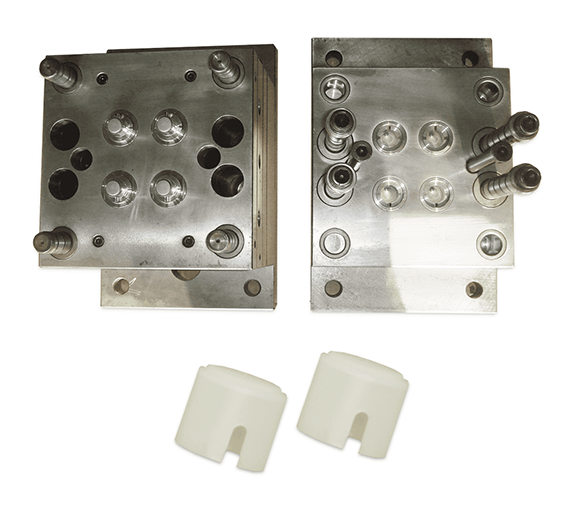

Lipstick Parts-2001

Why is the 2001 Lipstick Component Your Strongest Choice?

- Precision & Stability: Advanced mold design with premium steel ensures rock-solid accuracy in every dimension.

- Outstanding Efficiency: 4-cavity mold delivers four pieces in one cycle, maximising productivity.

- Extended Lifespan: 300,000–500,000 injection shots guarantee long-term cost efficiency.

- HIPS Material Friendly: Fully compatible with painting, silk-screen printing, and electroplating for flawless finishing.

- Upgraded Technology: Designed with UG/CAD and Moldex 3D for refined processes and smoother molding.

- Flexible Customisation: Tailored to meet diverse brand requirements and packaging formats.

Quantity

- Product Features

- Product Specifications

Product Features

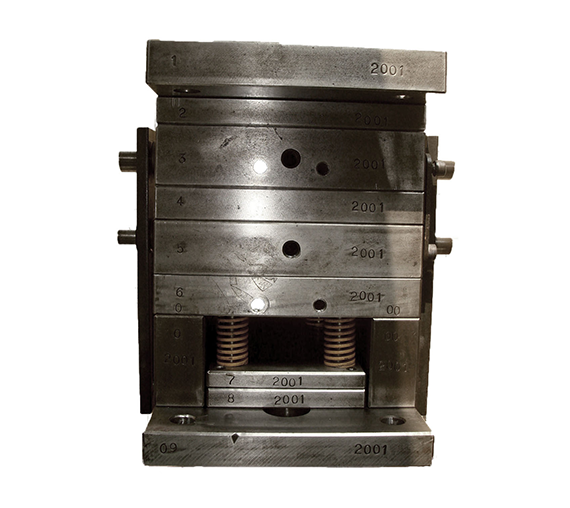

Plastic lipstick parts molds stand out for their high precision and durability. Precision mold design makes the lipstick parts consistent in size and improves production efficiency. Moulds made of stainless steel and carbon steel can provide a long life cycle and meet the needs of high-quality and high-capacity lipstick manufacturing. We also provide customized ODM/OEM services. Product Specifications

| Material | Stainless steel, carbon steel |

|---|---|

| color | Nickel White |

| Mold Base Supplier | Taiwan Dragon Kee |

| Mold base material | S50C |

| Core material | M310 |

| Number of holes | 4 holes |

| Runner | Cold sprue |

| Glue feeding method | Needle point nozzle |

| Mold life | 300,000~500,000 times |

| Design Software | UG, CAD |

| Mold flow software | Moldex 3D |

| Molding material | HIPS |

| Mold size | length: 200width: 300high: 285 mm |

| OEM and ODM | Acceptable |

| Packaging | Wooden box packaging or as your request |

Previous product

Previous product