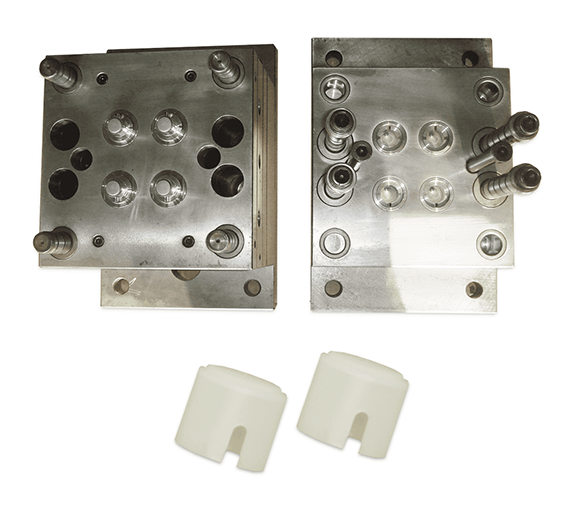

Eyebrow Pencil Cover Plastic Injection Mold 2316

Such parts are usually relatively small, so the eyebrow pencil cover plastic injection mold requires high-precision design, processing and manufacturing. To ensure that every manufactured part meets specifications. It also often has intricate shapes and details, such as the curve of the pen body, the shape of the nib, and the cap of the pen. The mold must accurately reproduce these details to ensure the appearance and function of the final product.

Quantity

- Product Features

- Product Specifications

Product Features

The plastic injection mold of the eyebrow pencil cap needs to have extremely high precision to ensure the part size is stable and consistent to avoid assembly errors. In addition, the eyebrow pencil caps have various shapes, including rotating opening and closing, anti-leakage design, snap-on structure, etc., which require complex and high-precision molds to be created based on product characteristics. To improve production efficiency and mold life, the mold must be made of highly wear-resistant steel and precision polished to reduce friction and loss. At the same time, the optimized cooling system can ensure rapid cooling during injection molding, improve the quality of the finished product and shorten the production cycle. We provide professional plastic injection mold development, and provide high-precision, durable and efficient solutions for eyebrow pencil covers, helping beauty brands improve their product competitiveness. Product Specifications

| Material | Stainless steel, carbon steel |

|---|---|

| color | Nickel White |

| Mold Base Supplier | Taiwan Dragon Kee |

| Mold base material | S50C |

| Core material | M310 |

| Number of holes | 4 holes |

| Runner | Cold sprue |

| Glue feeding method | Needle point nozzle |

| Mold life | 300,000~500,000 times |

| Design Software | UG, CAD |

| Mold flow software | Moldex 3D |

| Molding material | PP |

| Mold size | length: 200width: 300high: 250 mm |

| OEM and ODM | Acceptable |

| Packaging | Wooden box packaging or as your request |

Previous product

Previous product