Injection mold production/development

From Concept to Production – Custom Injection Mold Development

Clear & Transparent Mold Development Process

From your initial sketch or 3D file → DFM (Design for Manufacturability) analysis → Mold flow simulation → Technical drawing → CNC/EDM machining → T1 trial run.

Average lead time: 45 days to deliver the first T1 sample, with progress updates at every stage.

From your initial sketch or 3D file → DFM (Design for Manufacturability) analysis → Mold flow simulation → Technical drawing → CNC/EDM machining → T1 trial run.

Average lead time: 45 days to deliver the first T1 sample, with progress updates at every stage.

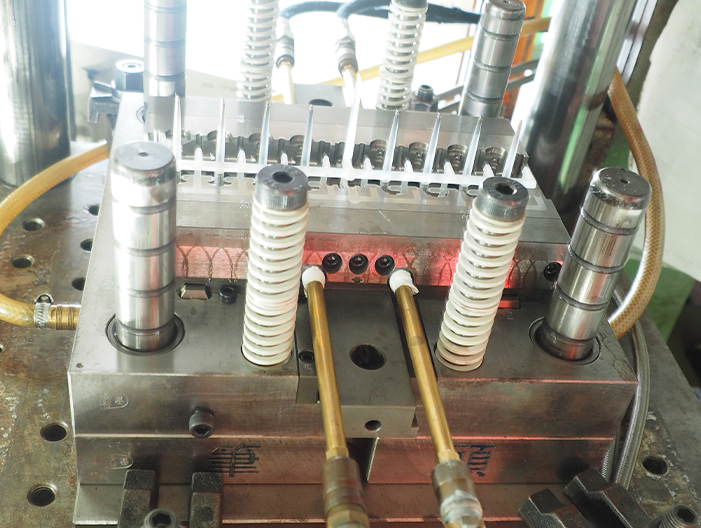

Expert Material Selection & Structural Design

Professional recommendations on mold steel and structural design, including multi-cavity, quick-change, and hot-runner systems to optimize cost and efficiency.

Professional recommendations on mold steel and structural design, including multi-cavity, quick-change, and hot-runner systems to optimize cost and efficiency.

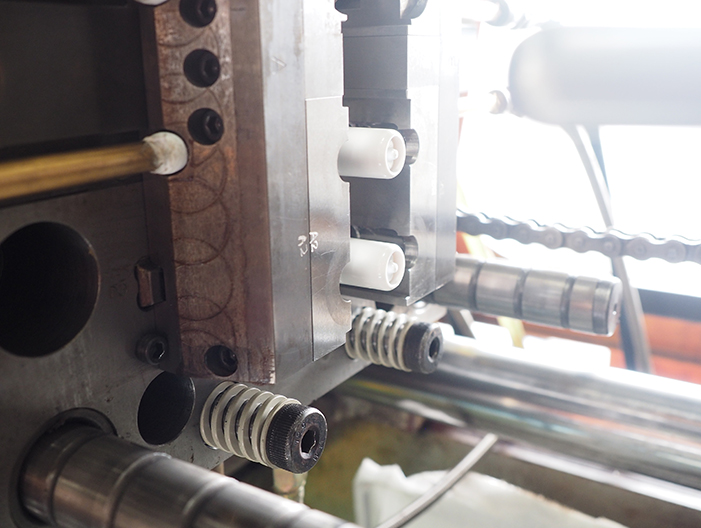

High Precision & Quality Assurance

Advanced CNC and EDM machining ensures ±0.01 mm accuracy.

Every mold includes a T1 trial report, mold lifespan estimate, and warranty terms.

Advanced CNC and EDM machining ensures ±0.01 mm accuracy.

Every mold includes a T1 trial report, mold lifespan estimate, and warranty terms.

One-Stop Service from Design to Mass Production

Integrated service covering product design, mold making, and injection molding, ensuring seamless transition to mass production with consistent quality.

Integrated service covering product design, mold making, and injection molding, ensuring seamless transition to mass production with consistent quality.

Lifetime Mold Warranty & After-Sales Support

One free mold maintenance per year.

When molds are mass-produced by CHII LEE, they are covered by a permanent lifetime warranty.

One free mold maintenance per year.

When molds are mass-produced by CHII LEE, they are covered by a permanent lifetime warranty.