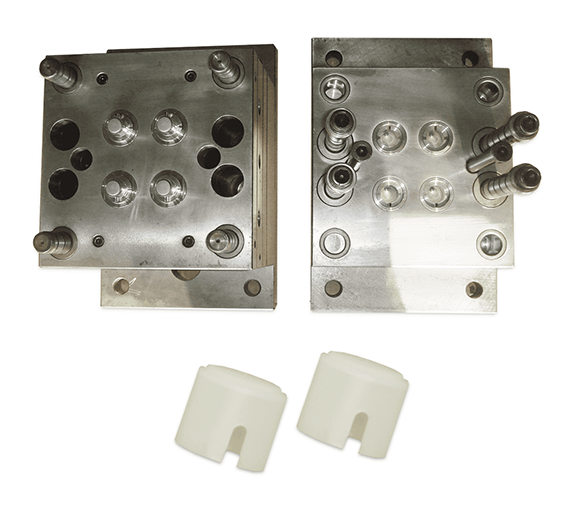

Lipstick bottom cover plastic injection mold-2611

High-precision plastic injection mold for lipstick bottom covers – ideal for custom cosmetic packaging production.

High Performance × High Quality

- Multi-Cavity Design: Commonly 4 cavities (customisable upon request), enabling multiple parts in one cycle to maximise production efficiency.

- Durable Lifespan: With a service life of 300,000–500,000 shots, the mold ensures stable mass production over time.

- Consistent Quality: Compatible with ABS material and subsequent surface treatments (spray painting, electroplating, UV coating, silk printing), delivering excellent product appearance consistency.

Quantity

- Product Features

- Product Specifications

- Packaging and delivery

Product Features

Mold Design & Durability

This type of lipstick plastic injection mold is typically designed for high-volume production, using multi-cavity designs such as 4-cavity, 8-cavity, or even 16-cavity configurations to increase efficiency.

Due to the frequent use in mass production, our molds are made from high-strength stainless steel or hardened tool steel, ensuring excellent durability.

We also provide lifetime mold maintenance and repair services to help customers extend the long-term service life and performance reliability of the mold.

Product Specifications

Mold specifications

| Product Name | High quality mould maker custom best ABS plastic lipstick base cap mold |

|---|---|

| Material | stainless steel, carbon steel |

| Color | nickel white |

| Standard | ISO9001 2015 |

| Mould Base | LKM |

| Mould Base Material | S50C |

| Core Material | M310 |

| Cavity QTY | 4 cavities |

| Runner | cold runner |

| Gate | Pin gate |

| Mould lifetime | 300,000~500,000 shots |

| Design software | UG, CAD |

| Mold flow software | Moldex 3D |

| Plastic part material | ABS-TOYOLAC 700 |

| Mould dimension | Length : 280 Width : 400 Height : 300 mm |

| OEM and ODM | Acceptable, also can be customize |

| Package | Wooden package or as your request |

Packaging and delivery

- Packaging Details: Wooden case with fumigation

- Port: Taichung Port

- Supply Ability: 80 Set/Sets per Year

Previous product

Previous product