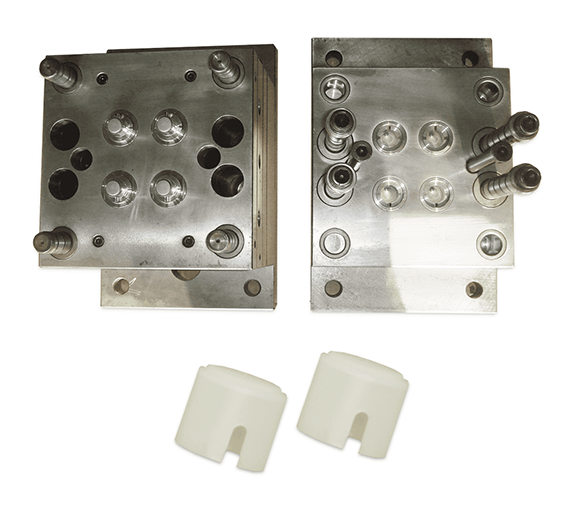

Plastic injection mold for powder box parts-2407

Quantity

- Product Features

- Product Specifications

Product Features

Details to pay attention to in the plastic injection process of powder box

As a cosmetic packaging material, powder boxes must not only have beautiful appearance, but also have good tightness, durability and a stable opening and closing mechanism. In the plastic injection process, special attention should be paid to the following details to ensure product quality and production efficiency:

1. Mold design and processing accuracy- High-precision mold production: The powder box structure usually contains fine parts such as hinges and buckles. The mold accuracy needs to be controlled at the micron level to ensure smooth assembly and avoid shaking or loosening.

- Demolding design: Due to the delicate shape of the powder box, the demoulding angle needs to be designed appropriately to avoid deformation or scratching of the product.

- Runner and gate design: Selecting the appropriate runner type (such as hot runner) can reduce material splashes, improve the smoothness of the finished product, and avoid surface defects.

- ABS: High toughness, impact resistance, suitable for powder boxes with hinged structures.

- AS: High transparency, suitable for transparent or translucent powder boxes.

- PS: Good rigidity, suitable for powder boxes that require a high-gloss appearance.

- Material drying: Some materials such as ABS and AS have strong water absorption and need to be fully dried before injection to prevent bubbles or atomization on the product surface.

Advantages and characteristics of powder box mold

- High Precision Design:Ensure the mold size is accurate to avoid deformation and demoulding problems.

- Optimized cooling system:Improve production efficiency and shorten injection molding time.

- Durable Materials:Made of high-quality steel to extend the life of the mold.

- Customized development:The design can be adjusted according to brand requirements to ensure that the product meets market demand.

Product Specifications

| Material | Stainless steel, carbon steel |

|---|---|

| color | Nickel White |

| Mold base supplier | Taiwan Dragon Kee |

| Mold base material | S50C |

| Core material | M310 |

| Number of holes | 4 holes |

| Runner | Cold sprue |

| Glue feeding method | Needle point water outlet |

| Mold life | 300,000~500,000 times |

| Design Software | UG, CAD |

| Mold flow software | Moldex 3D |

| Molding material | PP |

| Mold size | length: 300width: 400high: 275 mm |

| OEM and ODM | Acceptable |

| Packaging | Wooden box packaging or as your request |

Previous product

Previous product