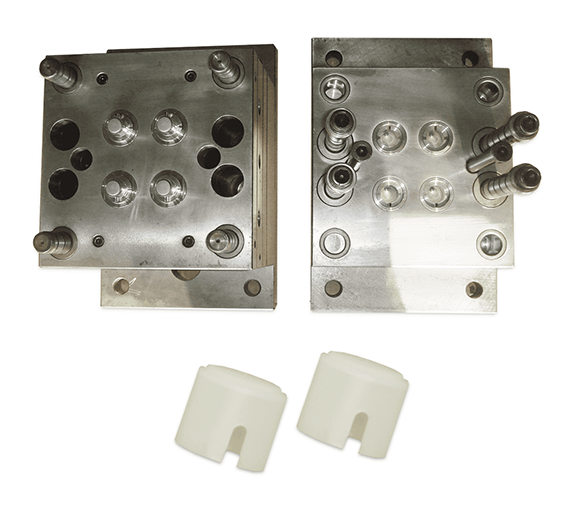

Pen cap plastic injection molding mold-2267

Pen Cap Injection Mold | High strength with 300,000–500,000 shot lifespan

PBT Molding Material | Highly durable & heat resistant

Specialised Pen Cap Mold | 4-cavity design for enhanced mass production efficiency

One-Stop Mold Service | Design / Manufacturing / Testing / Injection full-process support

Quantity

- Product Features

- Product Specifications

Product Features

The plastic injection molding process for making pen caps usually includes the following steps:1. Design the pen cap mold 2. Make the mold 3. Test the mold

4. Heating plastic 5. Injection molding 6. Trimming and inspection

The molds are manufactured and injection molded in Qili. We have a permanent warranty. We will not shirk our responsibilities. We will give you peace of mind.

Product Specifications

| Material | Stainless steel, carbon steel |

|---|---|

| color | Nickel White |

| Mold Base Supplier | Taiwan Dragon Kee |

| Mold base material | S50C |

| Core material | M310 |

| Number of holes | 4 holes |

| Runner | Cold sprue |

| Glue feeding method | Needle point water outlet |

| Mold life | 300,000~500,000 times |

| Design Software | UG, CAD |

| Mold flow software | Moldex 3D |

| Molding material | PBT |

| Mold size | length: 300width: 400high: 275 mm |

| OEM and ODM | Acceptable |

| Packaging | Wooden box packaging or as your request |

Previous product

Previous product