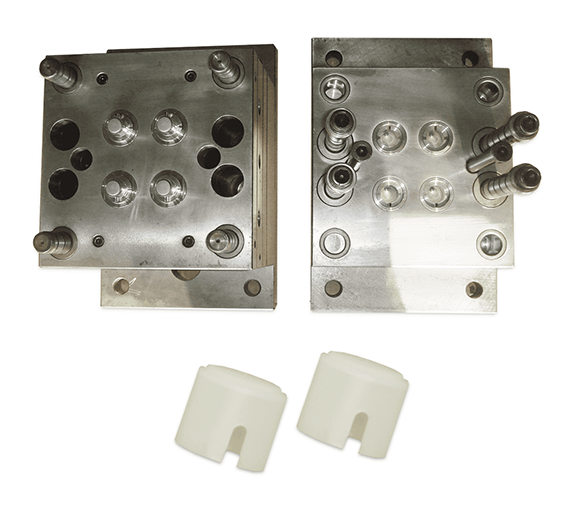

Lipstick Bottom Cover Plastic Injection Mold 2970

When manufacturing lipstick bottom covers via plastic injection molding, dimensional accuracy and visual quality are equally critical. They directly affect the structural integrity and visual consistency of the entire cosmetic packaging.

CHIILEE can customize molds according to client requirements to ensure high-precision dimensions, structural compatibility, and excellent assembly fit.

- Product Features

- Product Specifications

We apply strict appearance and dimensional control standards for cosmetic packaging parts, including:

- Surface flatness and edge uniformity after molding

- Glossiness and consistent color tone of the material surface

- Precision and fit with other components (e.g., lipstick cap, rotating core)

Throughout production, CHIILEE performs multiple appearance inspections. When necessary, we conduct edge trimming, polishing, and surface finishing to ensure every piece meets brand image expectations and end-user market demands.

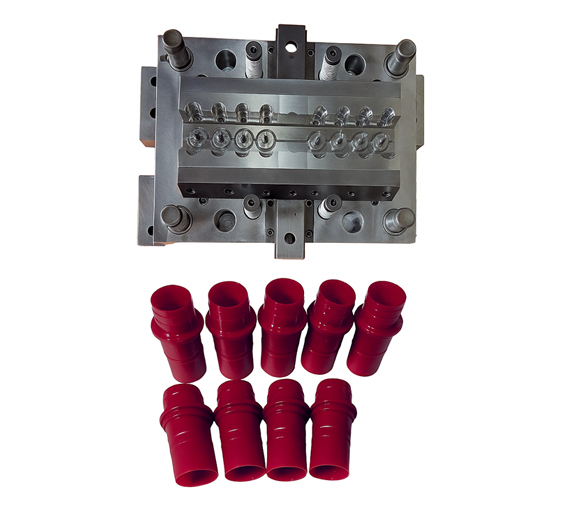

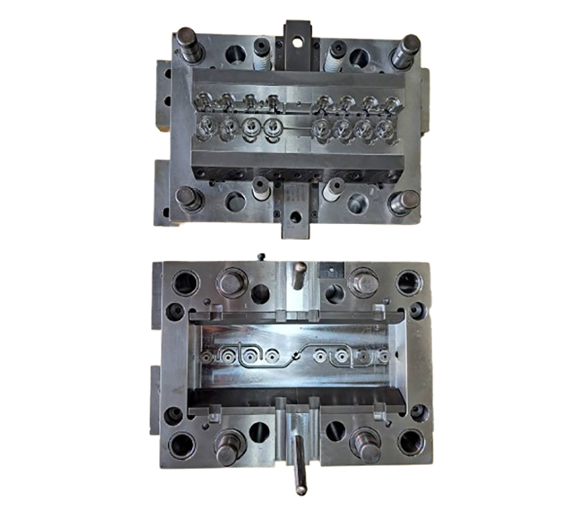

Furthermore, the 2970 mold adopts an 8-cavity cold runner design, achieving both high-volume output and product quality stability—ideal for medium to large-scale cosmetic brands engaging in mass production.

| Mold No. | 2970 |

|---|---|

| Application | Lipstick bottom cover |

| Mold Material | Stainless steel, carbon steel |

| Color | Nickel White |

| Mold Base Material | S50C (Supplier: Dewey) |

| Core Steel | STAVAX 420 |

| Resin | ABS |

| No. of Cavities | 8 |

| Runner | Cold runner |

| Gate Type | Large gate |

| Mold Life | 300,000–500,000 shots |

| CAD Tools | UG, CAD |

| Flow Analysis | Moldex 3D |

| Dimensions | Length : 400 Width : 300 Height : 300 mm |

| Packaging | Wooden crate or as per customer requirements |

| OEM / ODM | Accepted |

Previous product

Previous product