Integrated Exposure Machine-2491

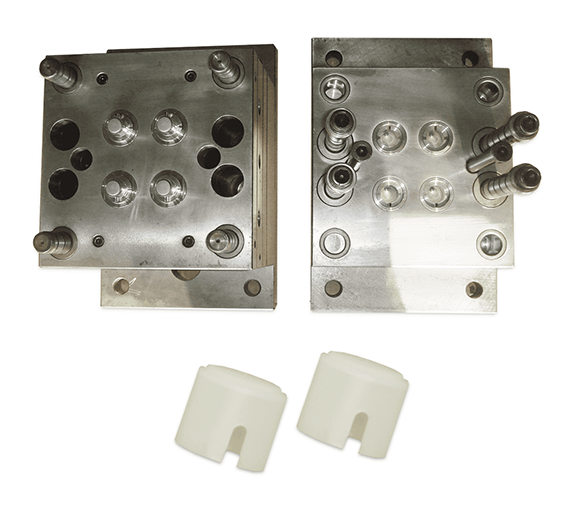

Made with stainless steel and carbon steel structure, featuring an S50C mold base and NAK80 mold core, this mold offers excellent heat dissipation and insulation to perfectly protect electronic components such as fingerprint sensors. Designed with a 4-cavity cold runner system, it supports PC material injection and provides a long lifespan of 300,000–500,000 shots. With UG/CAD + Moldex3D precision design processes, it fully meets high-efficiency production demands.

Quantity

- Product Features

- Product Specifications

Product Features

The mold design takes into account the heat that may be generated when the fingerprint reader is in operation to ensure good heat dissipation and avoid overheating that affects performance. Moreover, the mold gives the product good insulation properties to protect electronic components from interference from the external environment. Product Specifications

| Material | Stainless steel, carbon steel |

|---|---|

| color | Nickel White |

| Mold base supplier | Shiba |

| Mold base material | S50C |

| Core material | NAK80 |

| Number of holes | 4 holes |

| Runner | Cold sprue |

| Glue feeding method | Submarine gate |

| Mold life | 300,000~500,000 times |

| Design Software | UG, CAD |

| Mold flow software | Moldex 3D |

| Molding material | PC |

| Mold size | length : 250 width : 200 high : 270 mm |

| OEM and ODM | Acceptable |

| Packaging | Wooden box packaging or as your request |

Previous product

Previous product