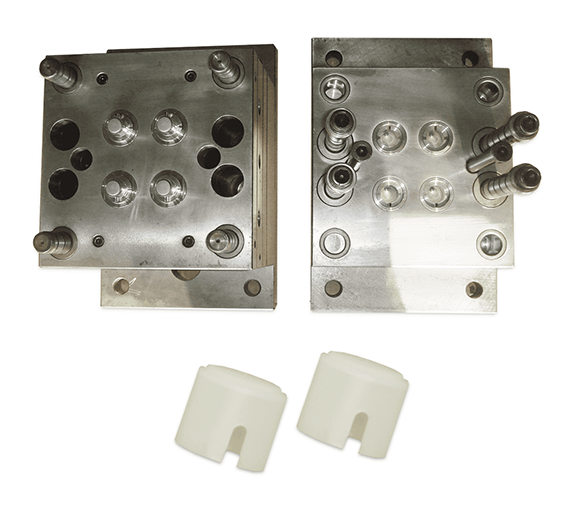

Electronic cigarette parts plastic injection mold 2600

Quantity

- Product Features

- Product Specifications

Product Features

The choice of plastic injection mold for electronic cigarette parts depends on the desired final product material. Generally speaking, the outer shell of e-cigarettes is usually made of engineering plastics such as ABS, PC, PVC, etc., while the internal parts may be made of different materials such as POM, PA, PC, etc.

Precision plastic injection technology for electronic cigarette shell

The shell design of e-cigarettes requires high-precision geometric structures, such as circles, openings, ventilation holes, etc., to ensure good airflow and sealing. To ensure the quality of the finished product, plastic injection molds must have the following characteristics:

- Efficient cooling system to ensure uniform molding

- Good exhaust system to reduce shrinkage and bubbles

- Precise demoulding design improves product stability

Common materials and advantages

The electronic cigarette shell needs to be both durable and beautiful. Common plastic materials include:

- ABS: Impact-resistant, strong and durable

- PC (Polycarbonate): High temperature resistance, good transparency

- PVC: Strong chemical resistance, suitable for specific needs

In addition, the product surface can be provided with a variety of treatments such as matte, glossy or metallic texture according to demand to enhance market competitiveness.

Product Specifications

| Material | Stainless steel, carbon steel |

|---|---|

| color | Nickel White |

| Mold base supplier | Taiwan Dragon Kee |

| Mold base material | S50C |

| Core material | M310 |

| Number of holes | 2 holes |

| Runner | Cold sprue |

| Glue feeding method | Direct gate |

| Mold life | 300,000~500,000 times |

| Design Software | UG, CAD |

| Mold flow software | Moldex 3D |

| Molding material | ABS |

| Mold size | length: 320width: 300high: 300 mm |

| OEM and ODM | Acceptable |

| Packaging | Wooden box packaging or as your request |

Previous product

Previous product