New knowledge-milling cutter introduction

1. Introduction

Milling cutterCommonly used forMilling MachineCutting workpiece to performMillingThe action of removing material at a fixed feed rate on the machine.

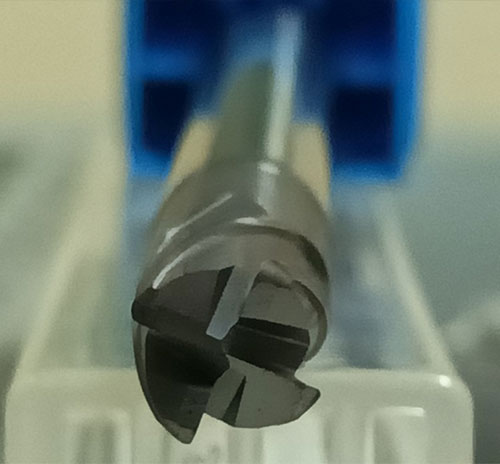

handleFor fixing on the knife bar

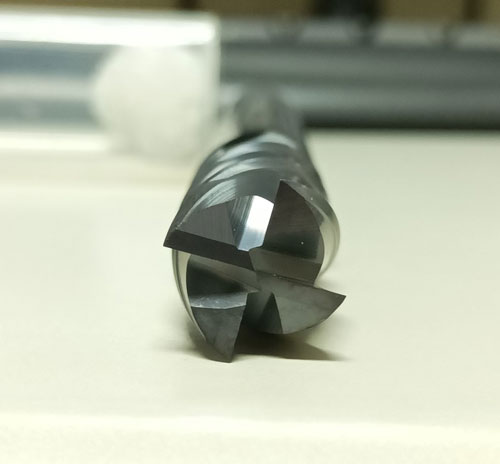

Cutting Edges: 2, 3 and 4 cutting edges are the most common, generally the more teeth a cutting edge has the faster it can remove material, so a 4-tooth cutter can remove material twice as fast as a 2-tooth cutter.

Helix angle: usually 30°~45°

Coating: Titanium carbonitride and titanium nitride films can increase the wear resistance of the tool and extend the life of the tool.

How is the tungsten steel milling cutter made?

Powder metallurgy: aMetal powderAs raw materials, pressed andsinteringProcessing methods for making various products.

Tungsten steel milling cutter: Tungsten carbide and cobalt are pressed and sintered into round rods, which account for 99% of all components and 1% is other metals. Then the knife factory uses a CNC grinder to grind out the blade of the milling cutter.

Product Packaging Instructions

S220 Series Product Packaging Instructions

- The main color of the packaging box cover is "yellow"

- Processing workpiece hardness below 55 degrees (general use series)

M520 Series Product Packaging Instructions

- The main color of the packaging box is blue

- Processing workpiece hardness below 60 degrees (high hardness series)

N620 Series Product Packaging Instructions

- The main color of the packaging box is red

- Processing workpiece hardness 45~65 degrees (high speed and high hardness series)

S220 Series Tool Features

- For processing low hardness materials (HRC55 and below)

- Using new coating and ultra-fine grade raw materials

M520 Series Tool Features

- For processing high hardness materials (HRC60 and below)

- Using new coating and ultra-fine micro-particle grade raw materials

- Higher wear resistance

N620 Series Tool Features

- For processing high hardness materials (HRC45~65)

- Using new coating and nano-grade raw materials

- The short blade design is suitable for high speed and dry cutting.

- The rounded corner design of the knife tip can reduce edge chipping.

- Higher wear resistance

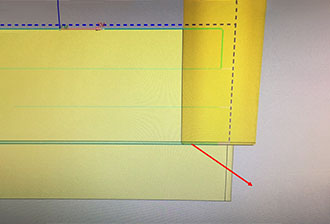

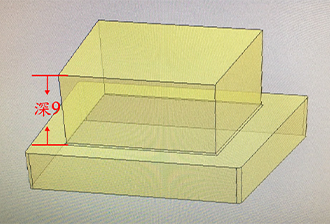

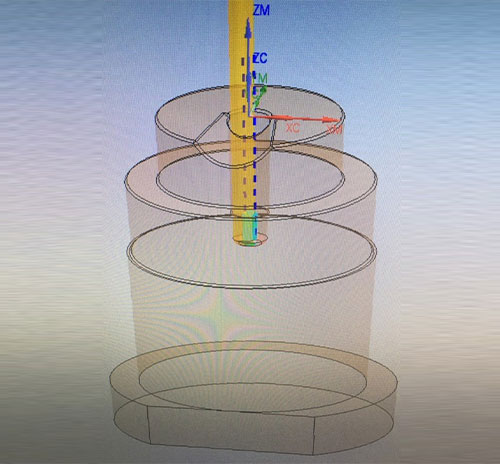

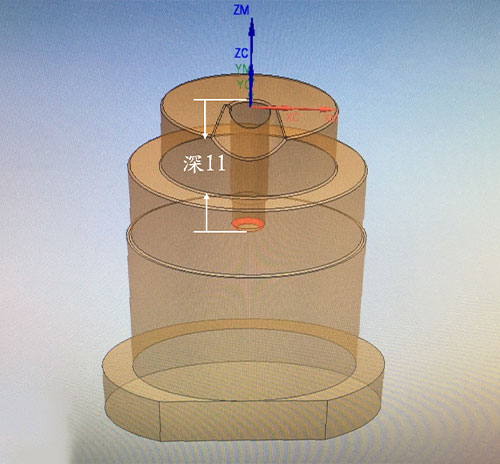

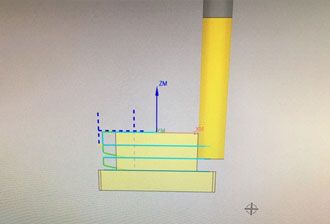

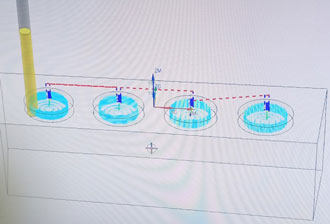

2. Types of milling cutters - flat milling cutters

※For milling flat and straight-walled workpieces

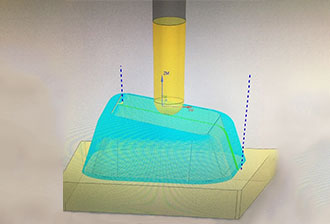

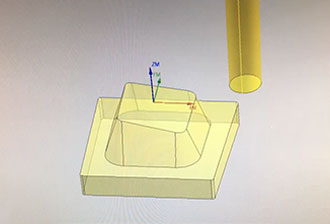

3. Types of milling cutters - ball milling cutters

※Used for milling irregular surfaces and inclined workpieces

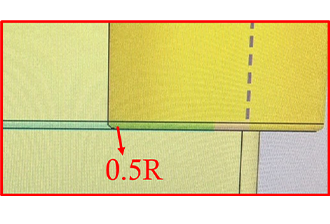

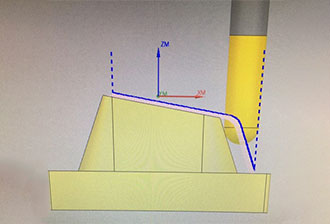

4. Types of milling cutters - round nose milling cutters

※For milling flat and inclined workpieces